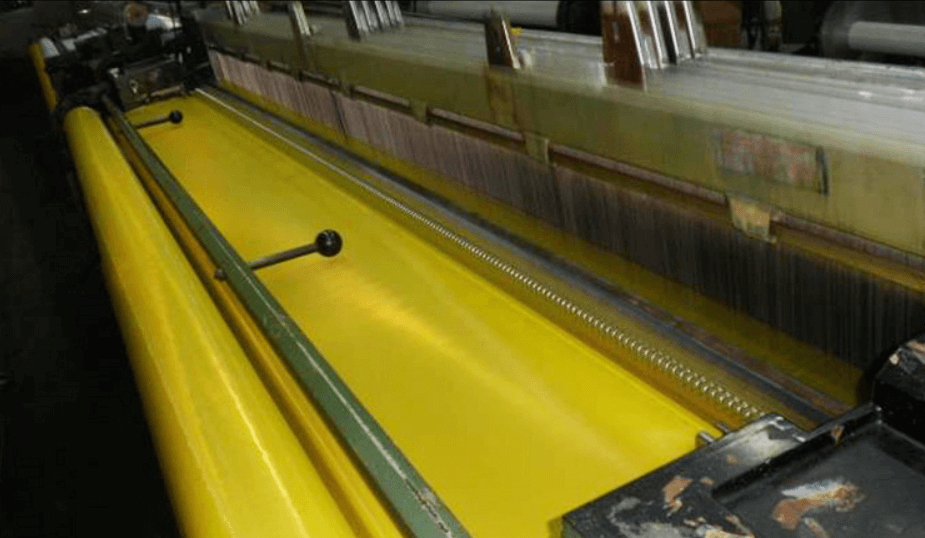

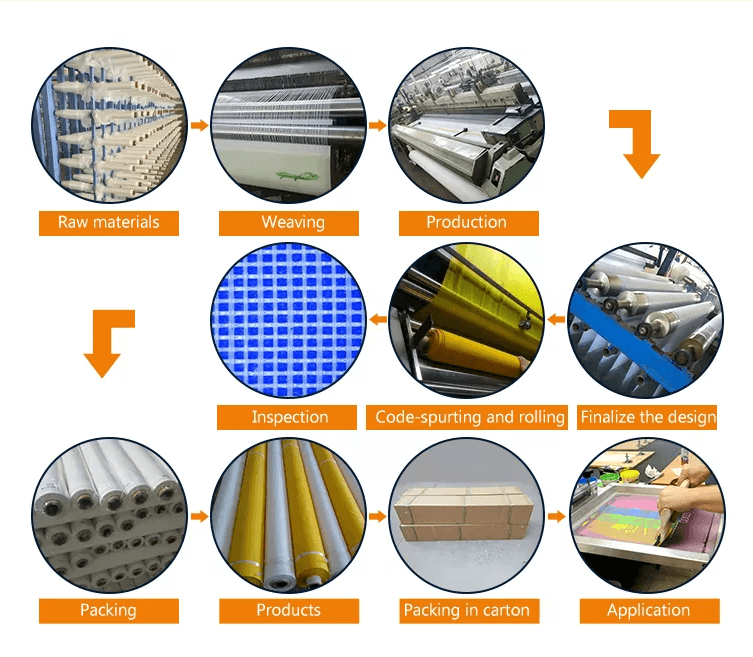

Polyester was introduced to the screen printing market over 40 years ago and quickly replaced traditional silk as the fabric of choice among screen printers all over the world. It is a material that is uniquely suitable for screen

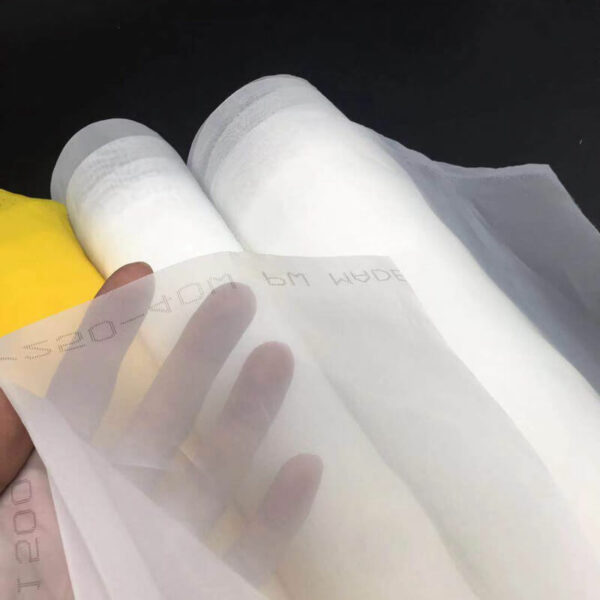

printing because of its tensile strength, elastic memory and resistance to chemicals, abrasion heat and moisture. There are 3 types of polyester fabrics used in screen printing and they are monofilament, low-elongation monofilament andmultifilament.

Most of today’s screen printers use monofilament polyester, but the traditional type is rapidly being replaced with “Low-Elongation” fabric, which brings many new benefits to the screen printing process. Here we mainly introduce low-elongation monofilament polyester fabric as this is what we are producing now.

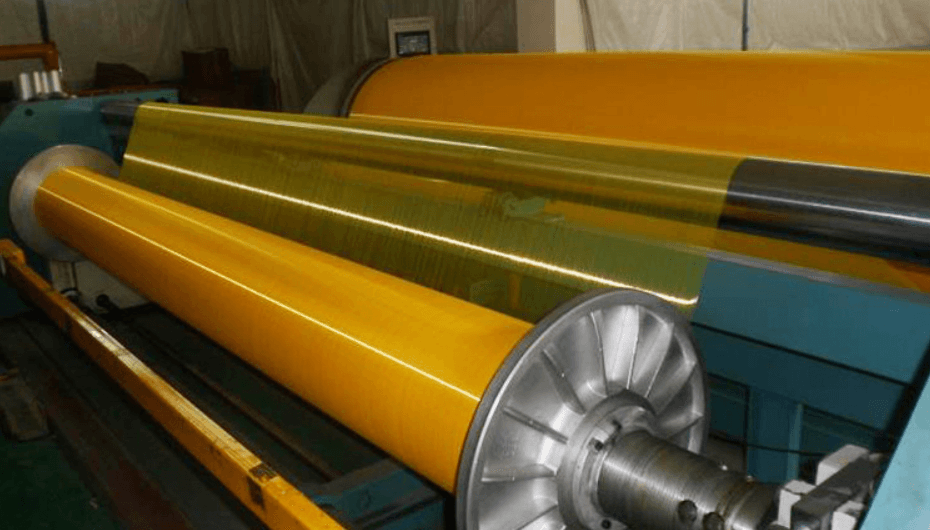

Monofilament Polyester is woven from yarn that is extruded from heated polyester into a single strand.

The extruded thread is the spun to a precise diameter. Conventional monofilament polyester screen fabric will elongate under tension: the higher the tension level, the more the thread can stretch. At excessive tension levels, the thread reaches its “plastic deformation” point, and the screen will no longer hold tension. Monofilament polyester is still suitable for non-critical printing applications.

In recent years, however, it has been eclipsed by a new development in thread technology: Low-Elongation Polyester.

Low-Elongation Polyester is what we are producing now in a wide range of mesh counts, and our products offers significant advantages over the traditional monofilament polyester.

Polyester monofilament is the best choice for textile screen printing.

Polyester is the most common for garment printing. Two different types of mesh weaves are available. Plain weave is a simple one-over/one-under pattern similar to a basket. This allows for a very sharp print when you are screen printingdetailed designs. Twill weave is a two-over/two-under pattern. This does not provide the sharp detail like the plain weave but it does allow for more ink to pass through the mesh at higher mesh counts. Most applications are best whenprinted with plain weave mesh.

Thread thickness is also very important. You may not realize it but many mesh counts that you order are available in different thread sizes. For example,43t mesh count is available in a thread thickness of 60, 80, and 100 microns. The 43t mesh count screen with 80micron thread best tension at (27 to 32 N/cm). the tighter screens for high-end printing , you also must consider the ink deposit between the different screens. Even though they are all 43tcount screens,they all have different theoretical ink deposits on different fabric thickness.

Mesh colour is also something to consider.

Customers often ask what the difference is between white and dyed mesh. White mesh has a tendency to refract light. This causes undercutting of your stencil and you can lose important detail. Yellow mesh reduces refraction because it reduces the travel of ultraviolet light. Dyed mesh will take a longer exposure time but it is a small price to pay when you could be losing fine lines and half-tones, so printing through meshes over 100T dyed mesh is preferred.

Using proper mesh tensioning procedures will allow for optimum print control and performance. It is important to understand that one definitive mesh tensioning level does not exist. Every mesh count, every thread diameter, and every thread material may tension at different levels.