Don't miss our holiday offer - up to 50% OFF!

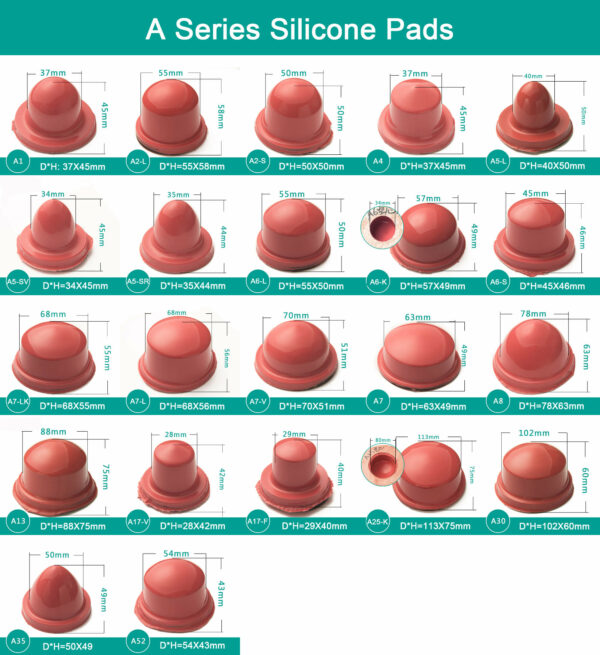

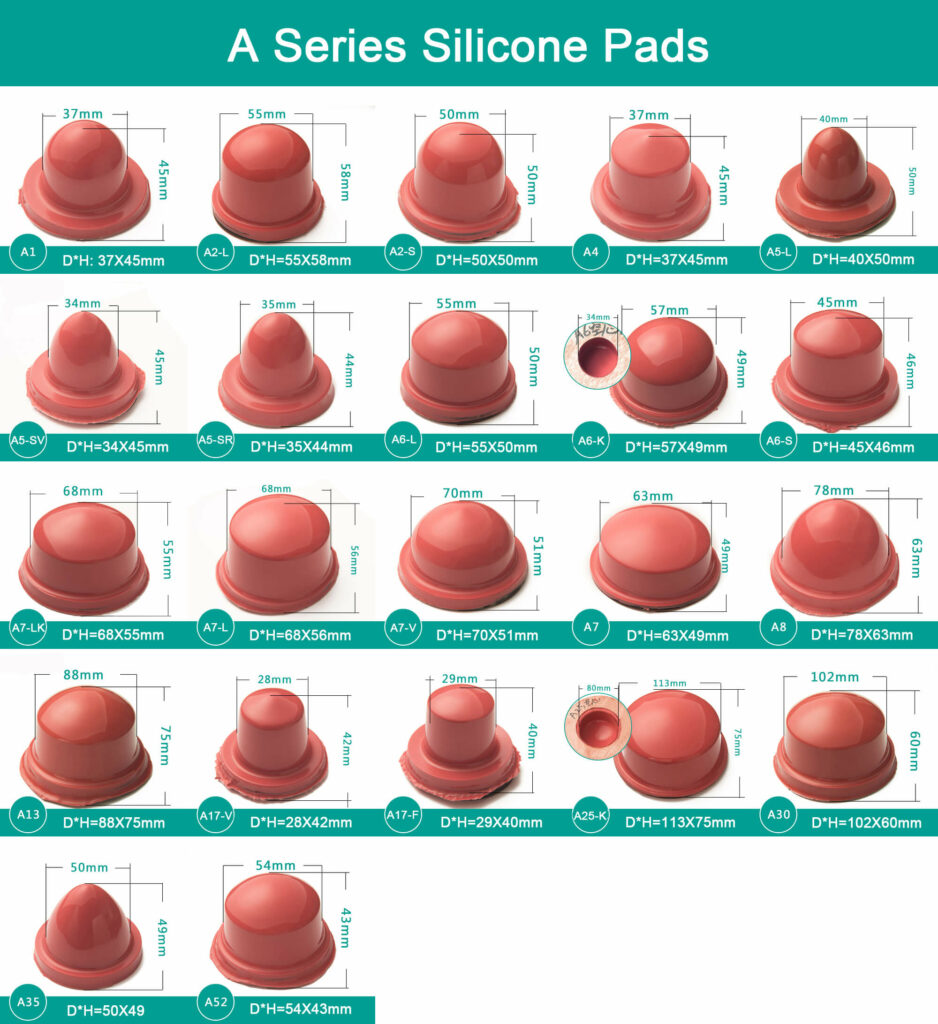

Pad Printing Silicone Rubber Pad/Head -A Series

Price range: $4.00 through $25.00

- Strength and resistance to solvents and inks for pad longevity;

- Various shape and size and hardness available for selection

- Pad size refers to: A Series, B Series, C series

- Hardness Type: Soft(3-10)/Medium(10-20)/Hard(20-30)

- Normal hardness 5 is used for manual pad printing machine,

- Normal hardness 25 is used for automatic pad printing machine

- Special size and hardness can be customized

- Color: Red, White, Blue , Green or made according to demand

- To pick the image up from a flat plane and transfer it to a variety of surface((i.e. flat, cylindrical, spherical,compound angles, textures, concave surfaces, convex surfaces).

| A Serise Pads | A1, A2-S, A2-L, A4, A5-L, A5-SR, A5-SV, A6-K, A6-L, A6-S, A7, A7-L, A7-LK, A7-V, A8, A13, A17-F, A17-V, A25-K, A30, A35, A52 |

|---|