Don't miss our holiday offer - up to 50% OFF!

Emulsion Hardener(A+B)

Original price was: $10.00.$8.00Current price is: $8.00.

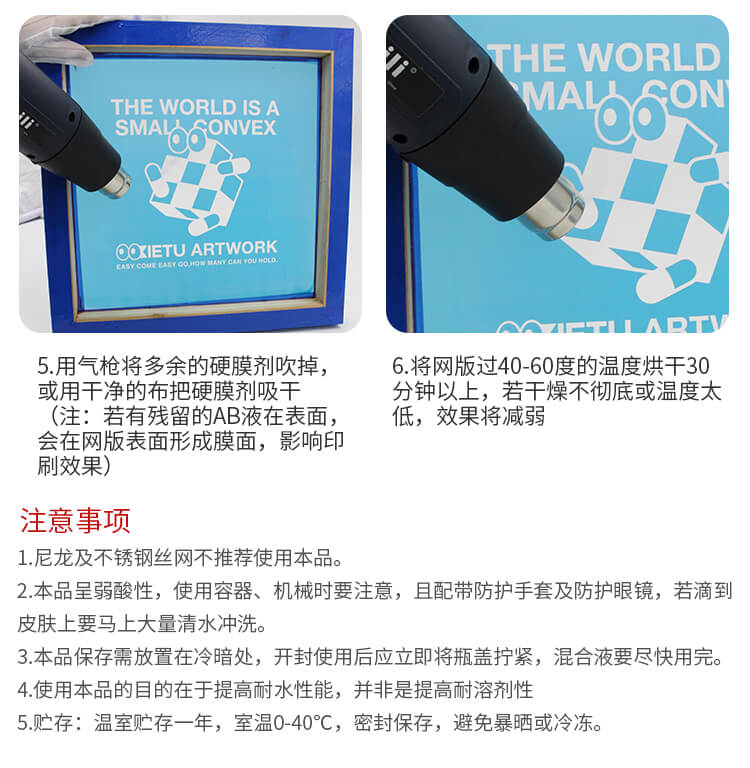

- A+B liq mixing,and ratio is 1:1

- Creates Stronger Emulsion Stencil

- Increases Water Resistance

- Non-Flammable / Hazardous

- Biodegradable & Drain Safe

- Reduce Emulsion Break Down

- Safe For Mesh

- Water-Based